In the fast-evolving world of manufacturing, precision, efficiency, and scalability have become more crucial than ever. Among the technological advancements transforming this sector, CNC cutting stands out as a game-changer.

By leveraging computer numerical control (CNC) technology, manufacturers can produce intricate designs, reduce errors, and streamline production processes. This innovation is not just improving quality—it’s reshaping the way businesses approach manufacturing.

Understanding CNC Cutting Technology

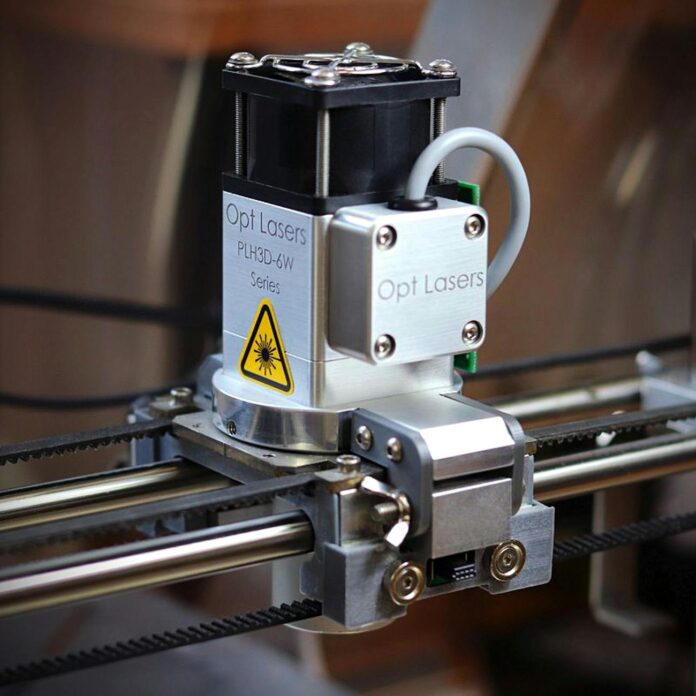

CNC cutting is a process that uses computer-controlled machines to cut, carve, or shape materials with extreme precision. Unlike traditional manual cutting methods, CNC systems follow pre-programmed instructions, ensuring consistency across each piece produced. These machines can handle a wide range of materials, including metal, wood, plastic, and composites, making them versatile tools in industries such as aerospace, automotive, and furniture manufacturing.

The main advantage of CNC cutting lies in its precision. Even the most complex designs can be executed with minimal error, which significantly reduces waste. For manufacturers, this translates into cost savings and higher product quality. Additionally, CNC machines operate continuously with minimal human intervention, boosting productivity and allowing businesses to meet increasing demand without compromising standards.

Benefits of CNC Cutting for Modern Manufacturing

Increased Accuracy and Consistency

One of the most significant advantages of CNC cutting is its unparalleled accuracy. The computer-controlled system ensures that every cut, drill, or carve follows the exact specifications. This consistency is particularly critical in industries where small deviations can lead to product failure or safety issues.

Enhanced Production Speed

CNC cutting dramatically accelerates production timelines. Automated processes eliminate the need for manual adjustments and reduce downtime between tasks. Manufacturers can complete more projects in less time, giving them a competitive edge in fast-paced markets.

Cost Efficiency

Although the initial investment in CNC machinery may be high, the long-term cost benefits are substantial. Reduced material waste, fewer errors, and lower labor requirements contribute to significant savings. Businesses can reinvest these savings into innovation and expansion, driving further growth.

Versatility Across Materials

CNC technology is compatible with a wide range of materials. Whether it’s metals for automotive components, wood for furniture, or plastics for prototypes, CNC machines can handle diverse requirements. This versatility allows manufacturers to cater to different industries without needing specialized equipment for each material type.

CNC Cutting Applications Across Industries

The applications of CNC cutting are vast and varied. In the automotive industry, CNC machines produce high-precision components such as engine parts, dashboards, and custom interiors. In aerospace, they help manufacture complex parts that require exact specifications to ensure safety and performance. Even in furniture and interior design, CNC cutting enables intricate designs that were previously impossible to achieve by hand.

Additionally, prototyping has become faster and more accurate thanks to CNC technology. Designers can create detailed models and test them before mass production, reducing errors and saving time. This approach is particularly valuable in research and development, where innovation depends on rapid iteration.

Finding the Right CNC Services

For businesses looking to integrate CNC cutting into their operations, selecting the right service provider is crucial. Accessing reliable and high-quality CNC router services near me ensures that manufacturers receive precise cuts, expert support, and timely delivery. Partnering with experienced CNC service providers can also offer insights into optimizing designs and production processes, further enhancing efficiency and product quality.

The Future of Manufacturing with CNC Cutting

CNC cutting is more than just a tool—it represents a shift in how manufacturing operates. As technology continues to advance, CNC machines are becoming smarter, faster, and more capable of handling complex tasks with minimal human intervention. Integration with artificial intelligence, robotics, and advanced software promises even greater efficiency, accuracy, and flexibility.

Moreover, as customization becomes increasingly important in the consumer market, CNC cutting offers the ability to produce tailored products at scale. Businesses can meet unique customer demands without sacrificing efficiency or quality. This adaptability positions CNC cutting as a cornerstone of modern and future manufacturing strategies.

Conclusion

CNC cutting is revolutionizing the manufacturing industry by offering precision, speed, and cost efficiency. Its applications span across numerous sectors, from automotive to furniture design, enabling manufacturers to produce high-quality products with minimal waste. As technology continues to evolve, CNC cutting will remain at the forefront of innovation, shaping the future of manufacturing and opening new possibilities for businesses worldwide.